How Recyclability Grades Are Determined Under PPWR — And What Businesses Should Do

The European Union’s Packaging and Packaging Waste Regulation (PPWR) is transforming packaging standards across Europe by imposing uniform rules on the design, sourcing, recyclability, reuse, and reporting of packaging materials. As a directly applicable regulation, PPWR establishes harmonized recyclability requirements that apply consistently across all EU member states.

Adherence to these recyclability grades under PPWR is pivotal for businesses seeking to comply, reduce packaging and Extended Producer Responsibility (EPR) costs, and maintain long-term market access. This comprehensive guide presents a deep dive into how recyclability grading is determined under PPWR and offers actionable steps for businesses.

1. What Is Recyclability Grading Under PPWR?

Recyclability grading assesses packaging based on its ability to be effectively collected, sorted, and recycled at scale within the existing European recycling infrastructure. The evaluation is grounded on how packaging performs “in practice and at scale,” emphasizing the use of common EU recycling technologies available across member states. The grading system thus measures recyclability beyond laboratory or theoretical conditions, focusing on realistic recycling outcomes.

2. Criteria Used to Determine Recyclability Grades

PPWR’s grading system evaluates packaging against five key criteria:

2.1 Material Composition

- Packaging made from single, homogenous materials, such as 100% PET plastic, polypropylene (PP), polyethylene (PE), or cardboard, demonstrates higher recyclability.

- Laminated or composite packaging that blends multiple materials difficult to separate reduces recyclability.

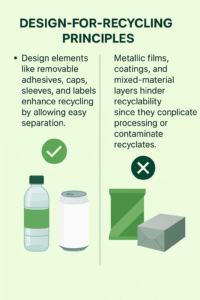

2.2 Design-for-Recycling Principles

- Design elements like removable adhesives, caps, sleeves, and labels enhance recycling by allowing easy separation.

- Metallic films, coatings, and mixed-material layers hinder recyclability since they complicate processing or contaminate recyclates

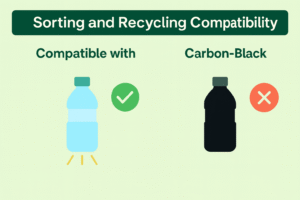

2.3 Sorting and Recycling Compatibility

- Packaging must be compatible with established sorting technologies such as Near Infrared (NIR) scanners used in Material Recovery Facilities (MRFs).

- Carbon-black plastics and non-detectable materials are challenging to sort, leading to decreased recyclability.

2.4 Quality of Recyclate Output

- Packaging earning high recyclability grades generates clean, high-quality recycled that can be reused in manufacturing without downcycling.

- Contaminated or multi-layer plastics typically reduce recyclate quality and lower grading.

2.5 Recyclable Mass Share

The actual fraction of packaging mass recyclable under prevailing collection and sorting systems is quantified; this percentage influences the overall recyclability grade.

3. PPWR Recyclability Grades (A to E) Explained

| Grade | Recyclability (%) | Description |

|---|---|---|

| A | ≥95% | Fully recyclable, monomaterial, compatible with existing recycling; produces high-quality recyclate. |

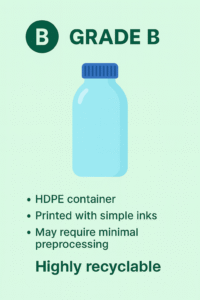

| B | ≥80% | High recyclability with possible minor pre-treatment or separation steps. |

| C | ≥70% | Recyclable but with limitations; some finite material loss or downcycling may occur. |

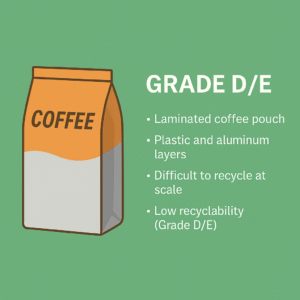

| D | 50–70% | Technically recyclable but not currently recycled at scale or in practice. |

| E | <50% | Non-recyclable or largely composite materials; packaging unlikely to be recycled effectively. |

4. Recyclability Grade Examples

- Grade A: PET bottle with polypropylene cap and removable label facilitates separation and recycling.

- Grade B: High-Density Polyethylene (HDPE) container printed with simple inks may require minimal preprocessing.

- Grade C: Paper carton with plastic window, with some material loss during recycling.

- Grade D/E: Laminated coffee pouch composed of plastic and aluminium layers, difficult to recycle at scale.

5. Market Access Deadlines Under PPWR

| Year | Packaging Recyclability Compliance Expected |

|---|---|

| Until 2029 | All recyclability grades (A–E) permitted |

| From 2030 | Only grades A, B, and C permitted |

| From 2035 | Packaging must be “recyclable in practice and at scale” |

| From 2038 | Likely only grades A and B accepted for market access |

These deadlines emphasize the progressive phase-out of poorly recyclable packaging and incentivize early adoption of recyclable designs.

6. What Businesses Should Do Now to Comply

Step 1: Packaging Classification

Conduct a comprehensive audit of all packaging by material type, weight, and current recyclability rating. This assessment forms the foundation for understanding your compliance status and identifying opportunities for improvement.

Step 2: Identify Risky Packaging

Flag packaging types prone to lower recyclability grades, such as laminates, composites, and non-detectable plastics. Prioritize high-volume or problematic packaging for redesign initiatives.

Step 3: Redesign Packaging

Optimize packaging design to use monomaterials, ensure easy separability, and avoid complex coatings and adhesives. Adherence to design-for-recycling principles improves grades and supports compliance timelines.

Step 4: Incorporate Post-Consumer Recycled (PCR) Materials

Where feasible, include higher PCR content to fulfill PPWR recycled content mandates and potentially improve recyclability perception and EPR fee modulation benefits.

Step 5: Deploy Reusable Packaging Solutions

Implement durable, returnable packaging formats in industrial and logistics supply chains to circumvent single-use packaging regulations and fees, particularly for B2B operations.

Step 6: Develop Packaging Master Data File

Maintain detailed packaging data files including supplier declarations, recyclability grades, weights, and compliance documentation to streamline reporting and audits. Use digital systems for easy tracking and updating.

Key Benefits of Compliance

- Market Access Protection: Secure continued access to EU markets post-2030 and beyond

- Cost Reduction: Lower EPR fees through high recyclability grades and PCR content

- Operational Efficiency: Streamlined supply chains and reduced waste management costs

- Sustainability Leadership: Enhanced brand reputation and consumer trust

- Regulatory Risk Mitigation: Proactive compliance reduces audit and penalty risks

Suggested Course of Action for PPWR-Compliant Packaging Transformation

- Conduct a comprehensive packaging audit across all product lines

- Classify existing packaging based on material type, recyclability performance, and likely PPWR grade

- Identify high-risk packaging (particularly Grade D and E) that will require redesign or phase-out

- Collect recyclability documentation and declarations from all packaging suppliers

- Develop redesign specifications focusing on monomaterial, recyclable, and PPWR-compliant formats

- Begin supplier collaboration for alternative materials, improved packaging formats, and PCR integration

- Implement a central digital system to track packaging materials, grade classification, PCR content, and supplier documentation

- Initiate pilot redesign projects for priority packaging formats with high-risk compliance gaps

- Transition fully to Grade A, B, or strong C packaging materials and structures

- Ensure supplier compliance through declarations, certifications, and mass balance verification where applicable

- Introduce reusable or returnable packaging systems for transport, industrial, or B2B packaging where applicable

- Establish continuous packaging monitoring and optimization processes to align with future PPWR updates, fee modulation, and recyclability performance thresholds

Conclusion

The PPWR recyclability grading system is a decisive factor for future-proofing packaging strategies in Europe. Packaging with grades A, B, or C secures market access post-2030 and reduces EPR fees, while grades D and E face increasing restrictions and phase-outs.

Businesses proactive in redesigning packaging towards high recyclability, embedded with PCR content, and complemented by reusable systems will not only mitigate regulatory risks but also enhance sustainability credentials and cost efficiency.

The time to act is now. Early adoption positions your organization as a leader in sustainable packaging innovation and ensures compliance with upcoming PPWR deadlines.

Disclaimer

The information in this article is based on the current text of the EU Packaging and Packaging Waste Regulation (PPWR) and publicly available policy documents at the time of writing. The regulatory framework is still evolving and may be further specified or amended through implementing acts, delegated acts, guidance documents, and national transposition or enforcement practices.

The recyclability grades, timelines, examples, and interpretations described here are provided for general information and educational purposes only. They do not take into account the specific nature, composition, or functional requirements of individual packaged products, nor the differences in collection, sorting, and recycling infrastructure that may exist between EU Member States, regions, or municipalities. Actual recyclability performance and compliance obligations may therefore differ from the generic scenarios illustrated in this article.

Nothing in this blog should be construed as legal advice, a formal compliance opinion, or a substitute for consulting with qualified legal, regulatory, or technical professionals. Businesses should seek tailored advice and verify requirements with relevant national authorities, Producer Responsibility Organisations (PROs), or competent legal counsel before making decisions related to packaging design, market access, or Extended Producer Responsibility (EPR) obligations.